Share this Post

PUBLISHED

August 30, 2021

READ TIME

5 Minutes

WRITTEN BY

![]() Dina Adlouni

Dina Adlouni

Dina is the resident Content Writer at EcoOnline North America . When she’s not writing about health and safety, you’ll find her enjoying a cup of tea while watching her favorite sitcom.

Risk Assessment, Analysis & Management in the Workplace

To protect workers on-site, safety professionals must conduct a thorough risk assessment to identify any potential hazards. Risk management is an essential part of any safety professional’s job to minimize injuries and illnesses on-site, ensuring the safety of the workforce. Without this process, you could be exposing your team to risks and hazards which could have been avoided.

Risk Assessment Process

The strength of your risk assessment process can be a leading indicator of the strength of your safety program. With proper steps in place, you can instill the foundation for a safer place to work.

Here are five steps to help you conduct your risk analysis:

1. Collect information about existing risks

It’s important to establish the current state of hazards and risks on-site. You can do this in several ways, including:

- Collecting the necessary documentation: Some information which may be available on-site can be found in your existing safety program, OSHA 300 and 301 logs which show a record of injuries and illnesses, worker’s compensation records, job hazard analysis documentation, and more. Have a look at these documents to gain a better picture of current risks which may be present at your organization.

- Speaking to the workforce: Talking to your team members can help you gauge certain hazards and risks. Make sure you speak to the necessary stakeholders and take their feedback into consideration, as they may be able to reveal risks which may not have been obvious in the above records.

- Using external sources: External sources may highlight prevalent risks and hazards in your industry. Consider the Occupational Safety and Health Administration (OSHA), Center for Disease Control and Prevention (CDC), and other leading organizations for more information on risks that are top of mind.

2. Conduct a thorough hazard inspection

Once you’ve gotten a better view of the risks on-site, it is helpful to conduct a new hazard inspection to assess any new risks which may have surfaced as processes have changed, tasks have altered, and new equipment or machinery wears down over time.

Read our blog, 5 Steps to Identify and Assess Workplace Hazards, to explore the different steps needed to conduct a proper hazard identification and assessment for maximum risk reduction.

3. Evaluate and analyze risks

Now that you have a better view of the risks which may be present on site, it’s time to analyze them and evaluate their severity. It is important to prioritize risks, as mitigating them all at once is not possible. Establish which risks are most severe and of the highest priority, who they could affect, and the necessary steps which need to be put in place to decide which risks will be at the top of the list.

4. Implement corrective actions

You’re now ready to mitigate risks by putting the necessary corrective actions in place. Speak with key stakeholders to help establish the best course of action to help eliminate any potential for injury or illness. If complete elimination is impossible, discuss ways to reduce risks by implementing certain PPE or engineering controls to help protect the workforce.

5. Review and undergo the risk assessment process as necessary

New risks and hazards could always arise on-site, so it’s important not to treat this as a one-time endeavor. The risk management process is one which you should regularly revisit to stay vigilant of any risks and quickly take measures to mitigate them if they do arise. As your risk management process evolves, so will your safety program so implement this process as necessary to create a safer work environment.

Risk Management Strategies

Managing risks on-site can be challenging, so it’s important to stay ahead of potential hazards with these risk management strategies. With these tips top of mind, you can move towards a more proactive safety approach.

1. Consider actionable metrics

The answer is always in the data. One of the most effective ways to mitigate risks is to keep your eye on real-time insights and information coming from your organization and workforce through robust reports.

Safety professionals can gauge how well their risk assessment controls and processes are working by looking at key safety metrics like leading and lagging indicators, total recordable injury frequency (TRIF), Days Away Restricted or Transferred (DART), Lost Time Injury Frequency Rate (LTIFR), and more. By assessing these injury frequency rates and strong leading indicators, you can get an accurate view of your safety performance and what can be done to improve it for maximum risk reduction.

Read our whitepaper, How to Convert Safety Data to Actionable Insights, to learn how to make these metrics your competitive advantage.

2. Regularly evaluate corrective actions

Another key risk management strategy is regularly evaluating corrective actions and controls which have been put in place to protect the workforce. As previously mentioned, new risks and hazards can always arise over time. Whether it’s due to new processes, equipment, or employees, it’s important for EHS professionals to keep their eye on controls to see if they are still effective or if new measures need to be put in place.

Safety professionals know this all too well with COVID-19 and its variants, for example. With temporary emergency standards released by OSHA and other changes to industry regulations, it’s important to stay vigilant of any changes and make sure they are implemented at your organization.

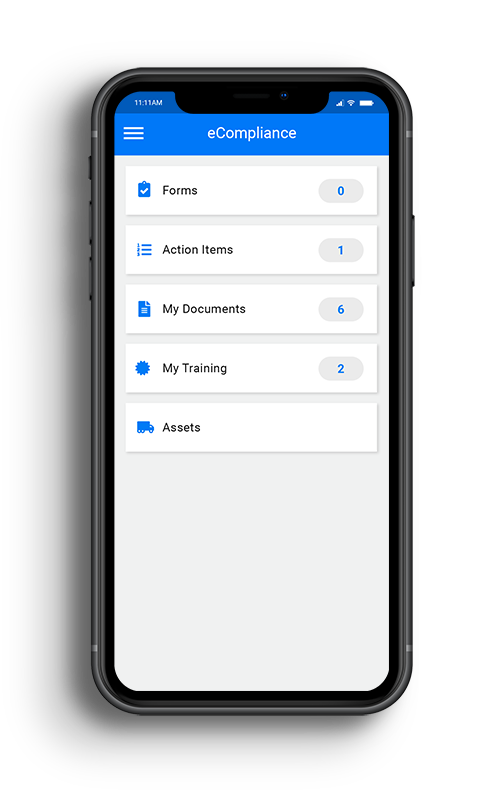

3. Implement a digital safety solution

Having a digital safety solution in place to help manage risks can be a game changer. With the ability to digitize and centralize all information in one platform, you can gain a 360 view into your safety program. This makes it simple to identify gaps and spot deficiencies you can work on. The ability to configure reports, inspections, and forms can also help you align the solution to your safety goals, so you are getting the exact information you need.

Risk management is a key component of a safe workplace and we want to help you optimize your process! With the EcoOnline suite of safety solutions, you can protect your workforce while driving safer outcomes in EHS management, asset inspection, and supply chain management.

Speak to one of our safety experts to learn more about how we can help you achieve safety success.

Learn How You Can Get EcoOnline North America

Complete this form and one of our safety experts will be in touch.