UPDATED

September 9, 2020

WRITTEN BY

Adrian Bartha

Share this Post

Injury Frequency Rates & Formulas You Need to Know

Calculating your lost time injury frequency rates is essential to assessing your organization’s safety performance. This KPI will help you examine certain trends when it comes to safety and the best actions to take to help mitigate risks and better protect your team members.

Before we dive into the specifics, let’s start from the very beginning…

What are Injury Frequency Rates?

Injury frequency rates are a way to normalize the number of injuries based on the number of hours worked on an annual basis.

Why Measure Injury Frequency Rates?

Everyone wants to know how their team is performing and if their actions are leading to improvements. Some of the many reasons to use these measuring sticks are to gauge:

1. Relative performance over time

– The feedback loop between action and results is especially important for leaders so they understand the true state of things. It also helps them to communicate effectively across the team.

2. Relative performance vs. peers

– This helps benchmark performance vs. industry averages and peer groups to know where they rank.

3. Absolute performance

– If your TRIF rate is 2.0, then approximately two colleagues are hurt every year per hundred employees; this helps frame the context around what your organization experiences in the production of it’s products/services.

What is TRIF? Let’s break it down…

TRIF, LTIFR, and DART Made Simple

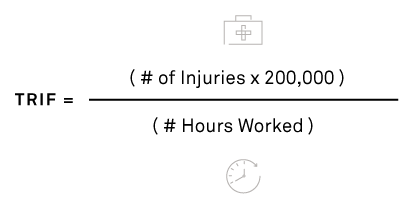

TRIF: Total Recordable Injury Frequency

Why 200,000? Because 100 workers working a 40-hour work week each year, is equal to roughly 200,000 hours. This tells you how many workers would get injured for every 100 employees worth of full-time hours worked. So, a TRIF of 4 means that if you theoretically had exactly 100 workers on a site working a 40-hour work week, you would have seen four recordable injuries in the year. This is probably the easiest way to think about it because it’s per 100 employees and easy to visualize.

If you wanted to do a quarterly TRIF, as some work sites do, you would take the injuries in any given quarter and replace 200,000 with 50,000 and the approximate number of hours worked.

Pros:

- It’s simple because you only need two pieces of data: number of incidents and hours worked.

Cons:

- Difficult for smaller companies because they may not have enough hours worked to create a TRIF with appropriate volatility.

- Injuries and hours are all weighed equally in terms of risk. Some companies will separate TRIF by divisions or types of work to better assess relative performance.

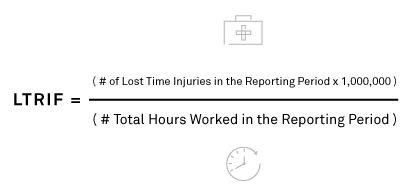

LTIFR: Lost Time Injury Frequency Rate

The key difference is LTIFR is calibrated to one million hours. For example, let’s imagine there were six lost time injuries in the past year at your company and a total of 2,500,000 hours worked. To calculate your LTIFR, simply plug those numbers into your formula: (6 x 1,000,000) / 2,500,000 to get a LTIFR = 2.4

Pros:

- Helps normalize for the actual hours worked and particularly helpful for larger organizations (calibrating to 1 million hours is approximately 500 full time persons over a year).

Cons:

- Same as TRIF.

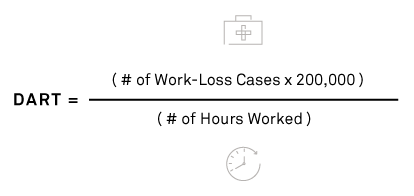

How to Calculate DART Incident Rate: Days Away, Restricted, or Transferred

Like the TRIF formula, DART considers the number of cases where an employee missed work from a work-related injury.

For instance, if you had two cases where an employee missed work from a workplace accident, your DART would be 2.0. (2 x 200,000) / 200,000 = 2

Pros of DART:

- DART considers the severity of injuries somewhat better than TRIF.

Cons of DART:

- DART treats 1 day away the same as 100, when presumably one hundred days away would be the result of a more serious injury and greater organizational risk.

What it Comes Down to is…Don’t Miss the Bigger Picture

Pick the Appropriate Rolling Averages

The use of rolling averages over 180 or 360-day periods may provide a better snapshot of recent performance as they are unaffected by arbitrary periods of a calendar year. Also, given that these are lagging indicators, evaluating performance 3-6 months after the launch of a safety initiative, leadership change etc. may provide a better link between actions and performance impact.

Measure the Positives

Instead of only measuring what goes wrong, you can also measure what goes right. This is particularly useful for an increasingly millennial workforce and for effective safety communications across your company. In eCompliance, many of our customers track positive recognition by supervisor and number of time, reviewing them for recurring trends and themes.

Leading Indicators are Even More Valuable

Consider what leading indicators best show where your organization is going instead of where it’s been. Depending on your organization’s safety maturity, you can get creative with indicators of risk BEFORE a negative event occurs and quantify this to measure over time.

Learn More

We’re just skimming the surface! There are so many things you can do to enhance your safety culture to protect your people. For more information, check out How to Leverage Your EHS Data to Improve Safety Outcomes.

Learn how eCompliance can help your safety program.

Complete this form and one of our safety experts will be in touch.