High Turnover

Means High Risk

Employees are the Most Valuable

Assets in Manufacturing

A highly skilled and competent workforce is a key factor of a successful manufacturing organization. This means safety leaders need to on the look out for everything from fatigue and falls to electrical burns and equipment failure.

The safest manufacturing companies trust eCompliance

Improve Your Safety Culture.

Save Lives. Reduce Costs.

Don't forget to enter in your text.

BOOK A FREE DEMO →

High Injury

Rates

118,000

Days away from work (DAFW)

incidents in manufacturing in 2016.

Manufacturing Industry Pain-Points:

✕ Cost-Conscious Operators

Constant pressure for cost savings and operational streamlining

✕ Critical Assets & Machinery

Ensuring all vehicles, equipment, tools, & assets are inspected & accounted for.

We Help Companies Like Toyota and Goodyear With:

✓ Demonstrating an ROI on Safety

Increase employee participation to improve productivity and reduce downtime.

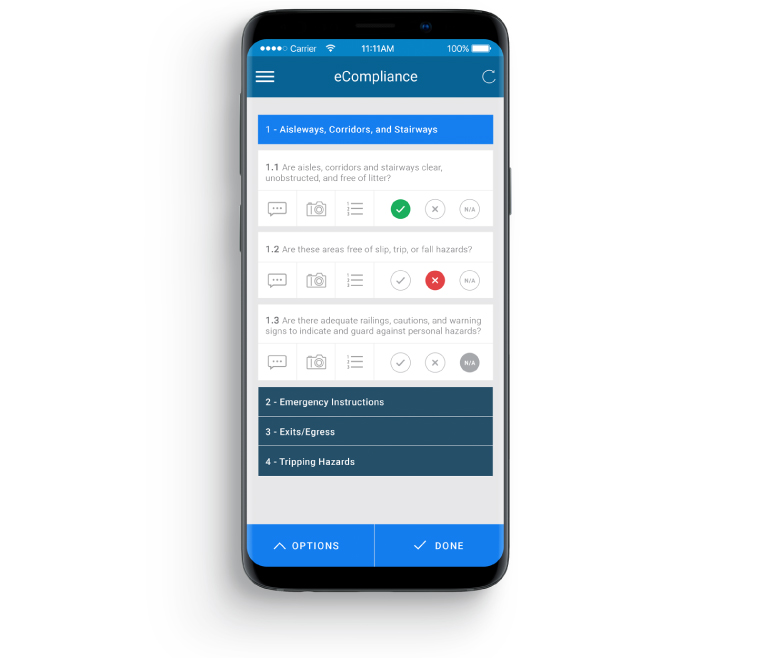

✓ Asset Tracking

Track everything with a simple app via a barcode scan, RFID scan or unique ID.

CASE STUDY

Benson Steel Slashes Inspection Times

50

Weekly paper inspections

10x

Inspections done 10x faster

VIEW CASE STUDY →

“Every morning I open up the inspections tab to check the graph showing completed inspections.

If I see a deviation in this graph,

I instantly know that someone

hasn’t been doing their job”

The Safest Manufacturing Companies Have 5 Things

in Common

Read about the 5 intentional steps that the world’s safest companies take on the way to building a workplace where, “Everyone is doing safety, every day.”