Share this Post

PUBLISHED

March15, 2021

READ TIME

6 Minutes

WRITTEN BY

![]() Dina Adlouni

Dina Adlouni

Dina is the resident Content Writer at EcoOnline North America . When she’s not writing about health and safety, you’ll find her enjoying a cup of tea while watching her favorite sitcom.

One of the main roles of a safety leader is identifying, assessing, and mitigating workplace hazards. Whether it’s an obvious occupational hazard or more implicit safety hazards, safety leaders must do all they can to protect their people on the worksite.

Creating a proactive approach and implementing a process to keep your team safe is a priority, and our team at EcoOnline is here to help you deliver better safety results.

According to the Occupational Safety and Health Administration (OSHA), the most effective controls to mitigate workplace hazards include the following 5 steps:

1. Collect existing information about workplace hazards

2. Inspect the workplace for safety and health hazards

3. Identify health-related hazards

4. Conduct incident investigations

5. Identify hazards associated with emergency situations

What Are Safety Hazards At a Workplace?

Let’s start off with the basics and define the term “safety hazard”. A safety hazard is any potential risk on the worksite that could cause a person harm. There are several types of hazards in the workplace, regardless of industry, and it’s important to be able to identify and recognize them all.

The most common workplace hazards

Hazards on site can come in several different forms. Here’s a snapshot of some common categories according to the Canadian Centre for Occupational Health and Safety (CCOHS):

- Safety Hazards: Safety hazards are any risks associated with the workplace including those associated with equipment and tools on the worksite, in addition to potential hazards that could result in slips, trips, and falls.

- Physical Hazards: Physical hazards are those that have the potential to harm someone physically causing injury, illness, or death. These range from temperature and noise to indoor air quality and radiation.

- Chemical Hazards: These hazards come from chemicals which could be potentially dangerous to humans and result in illness, injury, or death.

- Ergonomic Hazards: Ergonomic hazards are related to injuries resulting from the actions involved in a person’s role. This includes everything from lifting heavy equipment to typing on a computer.

Hazard Identification and Assessment

Mitigating and eliminating hazards on the worksite is a priority for all health and safety professionals, as it is their duty to create a safe working environment for team members. This includes implementing a proper process for hazard assessments and identification. Ready to dive in?

Your journey to creating a safer work environment starts here!

Step 1: Collect Existing Information About Workplace Hazards

The first step to mitigate workplace hazards, according to OSHA, is to gather information about those which already exist on-site. This can be done in a multitude of ways including looking at hazards recorded in previous hazard assessments and inspections, analyzing job hazard analysis, speaking to front-line workers and team members about risks on-site, in addition to taking a deep dive into your Total Recordable Injury Frequency (TRIF), Total Recordable Incident Rate (TRIR) and Days Away, Restricted or Transferred (DART) rates over time.

You can also collect information about hazards by looking at guidelines outlined by reputable organizations such as OSHA if you are located within the United States or Certificate of Recognition (COR) if you are within Canada. This will help ensure you are considering all possible safety hazards, even if they have never been recorded on your particular site.

Ensure your workplace safety assessments abide by regulations with OSHA compliance software.

Step 2: Inspect the Workplace for Safety Hazards

Next, inspect your workplace for possible hazards which may appear after a certain amount of time has passed. For instance, new hazards can arise when procedures change, new tools are used, or job tasks are altered.

This is most certainly a team effort as all sites and locations needs to be inspected for all types of health and safety hazards. Create a streamlined list and let your colleagues know what to look for such as hazards related to slips, trips, and falls, general housekeeping, and ergonomic issues, to name a few. Record all notable elements and start considering corrective actions that can be applied to mitigate risks.

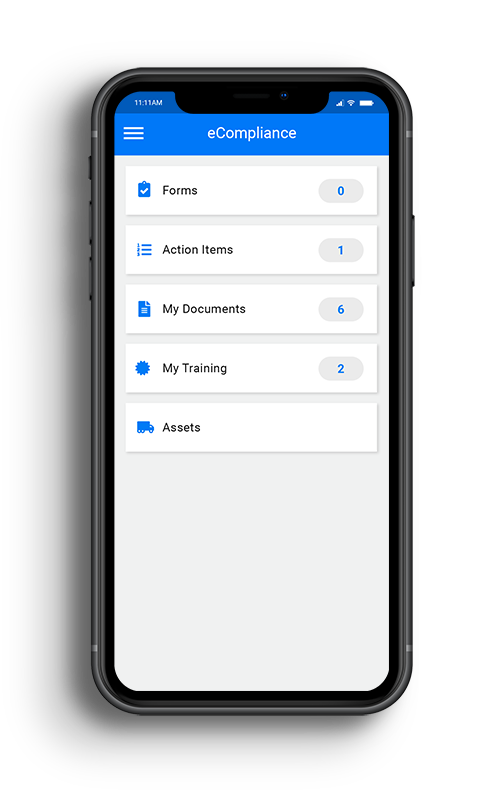

Don’t forget to inspect your equipment as well to ensure it is up to compliance standards. Check out our cutting-edge safety solution, EcoOnline Field iD to help you efficiently inspect assets.

Step 3: Identify Health-Related Hazards

After collecting information and inspecting your workplace, it’s time to identify health hazards. These can be more difficult to single out as they may be invisible to the naked eye, such as the ever-present COVID-19 virus. Another element which makes this hard to identify is some hazards have immediate risks whereas others take time to appear. OSHA recommends taking the following steps to efficiently identify health-related hazards, with those relating to the coronavirus explored more closely here.

As we previously mentioned, there are several types of hazards that could be found on a worksite which fall into the categories mentioned above. Take the time to review each category such as chemical hazards, ergonomic hazards, safety physical hazards, etc. to pinpoint any harmful chemicals, job activities, physical elements and so on that may pose a risk to your team members.

Remember to also be aware of any preexisting medical conditions team members may have when assessing health-related risks on-site. If you find a front-line worker has back problems, for instance, be wary of asking them to lift heavy objects.

Step 4: Conduct Incident Investigations

Now, it’s time to conduct incident investigations. This involves analyzing all incidents which have already occurred on-site and could potentially occur, ranging from near misses to actual injuries. The goal here is to establish what the source or root causes of the incident was and keeping an open mind that several factors could be at play.

Create a proper procedure to help pinpoint an occupational hazard, involving selected team members who conduct such investigations, recording all elements related to the incident. Once everything has been recorded such as what lead to the incident, what corrective actions were taken, how knowledgeable was the worker using these tools and carrying out this job task, etc., it’s vital to be as transparent as possible and close the feedback loop with workers and management. Once everything has been analyzed, team members can take the proper measures to ensure this doesn’t happen again.

Step 5: Identify Hazards Associated with Emergency Situations

The final step to efficiently identify and assess workplace hazards is to identify hazards that may not always occur daily, but instead may only arise during an emergency. For instance, what will happen if you have a COVID-19 outbreak on-site? This is something health and safety professionals have had to consider when modifying their health and safety programs and implementing new protocols.

In this step, consider scenarios which may be unlikely but could still happen. This includes an illness outbreak like COVID-19, a fire, an explosion, natural disasters, chemical spills, etc. If we have learned anything, it’s that we must plan for the unexpected to efficiently protect our people.

Our team at EcoOnline wants to help you properly identify and assess workplace hazards, collect and gather the necessary data and information, and work to put the proper systems and procedures in place to create a safer work environment. Speak to a safety expert and find out how our full-business solution can help by filling out the form below! Safety excellence starts now.

Resources:

- https://www.buildingsolutions.com/industry-insights/construction-safety-6-action-steps-to-identify-and-control-workplace-hazards

- https://ccohs.ca/topics/hazards/

- https://www.ehsinsight.com/blog/4-ways-to-control-hazards-and-risk-in-the-workplace

- https://fitforwork.org/blog/identifying-workplace-hazards/

- https://www.osha.gov/shpguidelines/hazard-Identification.html

- https://www.osha.gov/coronavirus/safework

- http://phnews.org.au/six-steps-to-control-workplace-hazards/

Learn How You Can Get EcoOnline North America

Complete this form and one of our safety experts will be in touch.