Share this Post

PUBLISHED

November 8, 2021

READ TIME

7 Minutes

WRITTEN BY

![]() Dina Adlouni

Dina Adlouni

Dina is the resident Content Writer at EcoOnline North America . When she’s not writing about health and safety, you’ll find her enjoying a cup of tea while watching her favorite sitcom.

Top 10 Most Common OSHA Violations

Every year, the Occupational Safety and Health Administration (OSHA) releases the top 10 OSHA violations to help safety professionals keep up with the most common standards, which have been violated that year and create a safer work environment. It is imperative that every safety professional is aware of common OSHA violations to help protect the workforce and stay away from hefty fines.

Although the top OSHA violations for 2020 have not changed from 2019, the positions on the list have shifted with the pandemic in full swing in 2020. Ranging from fall protection to ladder safety, these OSHA violations are preventable with the help of the right procedures and processes in place.

EcoOnline is here to help you reduce the number of injuries and illnesses on-site with tips from our experts on how to avoid the following top ten OSHA violations and the hefty fines they carry.

Let’s get started!

1. Fall Protection – Construction (29 CFR 1926.501)

Known as one of OSHA’s Fatal Four, falling is one of the most common causes of fatalities in the construction industry. For this reason, fall protection holds the number one spot for top 10 OSHA violations for the past ten years!

To help protect workers from falls from a height of six feet or more, proper safety systems must be put in place such as safety nets, barriers or railings on edges, and/or personal harnesses. Certain surfaces must also be tested so workers do not accidentally fall through them. In 2019, there were 5,424 violations related to fall protection, so make sure you are up to date with OSHA’s fall protection standard to properly assess walking and working surfaces.

Read more on fall protection directly from OSHA.

2. Hazard Communication – General Industry (29 CFR 1910.1200)

Second on the list is hazard communication, which entails communicating specific risks related to hazardous chemicals which may be on-site. The workforce and all employees should be told about these hazards and receive the necessary training related to hazardous chemicals. These elements and more can be outlined in a hazard communication program, which your organization should have.

Safety data sheets must also be maintained, kept up to date, and easily accessible by employees. All chemicals must also be labelled, and workers must be able to read the labels easily, which can be an aspect included in their training.

Read more on hazard communication directly from OSHA.

3. Respiratory Protection – General Industry (29 CFR 1910.134)

With the world in the midst of the pandemic in 2020, it’s no surprise that respiratory protection became a top priority and concern. EHS professionals must do all they can to protect the health of their workers, including measures to protect their respiratory systems.

The worksite must be properly ventilated, workers must have access to the right kind of Personal Protective Equipment (PPE), as well as respirators. The workforce must also receive the necessary training when it comes to protecting themselves from such respiratory risks and learning to use the right tools to stay safe. EHS professionals should have a respiratory protection program in place to outline all elements related to keeping their workforce safe from harmful substances or chemicals, easily accessible by all employees and inspectors.

In response to the pandemic, OSHA introduced a guide on mitigating and preventing the spread of COVID-19 in the workplace. This includes the 7 steps to correctly wear a respirator at work. On September 16, 2021, The Center for Disease Control and Prevention (CDC) has also provided strategies for optimizing the supply of N95 respirators.

Read more on respiratory protection directly from OSHA.

4. Scaffolding, General Requirements – Construction (29 CFR 1926.451)

Having the right scaffolding in place can help keep workers safe when it comes to heights and falls. That’s why someone who is qualified must design scaffolds and ensure they are able to support at least four times the maximum weight of the load which is put on it.

Certain controls like barriers and guardrails must also be put in place to prevent falls and all scaffolds must be inspected regularly. Workers must also be trained on what to do and what not to do when working on a scaffold to avoid injury.

Read more on scaffolding directly from OSHA.

5. Ladders – Construction (29 CFR 1926.1053)

Thousands of ladder violations occurred in 2020. With the right elements, these violations can be easily avoided. Ladder safety is of the utmost importance as they are a common tool used by workforces on worksites around the world.

Some tips to help you avoid injuries and violations related to ladders include training all employees on how to properly choose, inspect, and use ladders while working. If a ladder is damaged it must be removed from the worksite. Ladders must also always be used on a surface which is level and firm and should be able to support a certain amount of weight.

Read more on ladder protection directly from OSHA.

6. Control of Hazardous Energy (Lockout/Tagout) – General Industry (29 CFR 1910.147)

Controlling hazardous energy which may result from poor lockout/tagout procedures of specific machinery and equipment is essential, as this could lead to severe injuries such as burns, electric shocks, and more.

EHS professionals must have a written procedure of proper lockout/tagout steps which all employees must be trained on for their safety. All equipment must also be regularly inspected to protect against malfunction or damage. Speak to one of our safety experts to learn more about the EcoOnline asset management solution to help you proactively inspect assets and maintain equipment.

Read more on lockout/tagout directly from OSHA.

7. Powered Industrial Trucks – General Industry (29 CFR 1910.178)

Ensuring workers are properly trained on powered industrial trucks including tractors, forklifts, motorized hand trucks, and more is an OSHA requirement. Injuries from strike by’s and rollovers could result from inadequate training and use of such equipment.

All workers must be trained according to OSHA standards and retrained whenever a new industrial truck is introduced, any procedures related to the equipment has changed, or if the powered industrial truck has been involved in an incident. EHS professionals must make sure that training is given to the workforce by someone who is competent and has the expertise.

Read more on powered industrial trucks directly from OSHA.

8. Fall Protection – Training Requirements (29 CFR 1926.503)

With fall protection being the top violation for ten years in a row, it’s no doubt that training requirements related to fall protection would be one of the most common OSHA violations. Not providing adequate training on fall protection systems and fall hazards are things organizations and EHS professionals must avoid.

Workers must be thoroughly trained on how to recognize hazards and risks related to falling, as well as how to mitigate them with the right systems in place. They must also be trained to assemble, inspect, and maintain fall protection equipment.

Read more on fall protection training requirements directly from OSHA.

9. Eye and Face Protection (29 CFR 1926.102)

The workforce must be provided with the appropriate eye and face protection to keep them safe when working with chemicals, flying objects, etc. on-site. Failure to do so could lead to injuries including blindness and more.

The workforce must be trained on how to properly use the equipment and other protective systems, like eyewash stations, and should be reminded to always wear the allocated PPE for their job task for their own protection.

Read more on eye and face protection directly from OSHA.

10. Machinery and Machine Guarding – General Requirements (29 CFR 1910.212)

Last, but certainly not least on the list of top 10 osha violations, is machinery and machine guarding. Workers must be protected from equipment with the installation of the appropriate guards to keep them safe from any hazards related to using specific machinery.

Read more on machinery and guarding directly from OSHA.

Staying ahead of OSHA violations is an essential part of every EHS professional’s job and EcoOnline is here to help you create a safer work environment. Check out our blogs on how to mitigate risks in the workplace, including Risk Assessment, Job Hazard Analysis, 8 Workplace Safety Tips for Every Employee, and more.

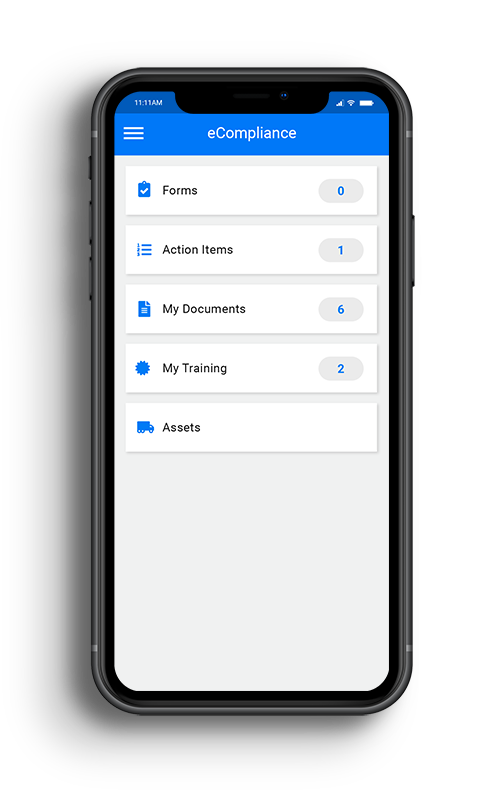

EcoOnline has a suite of safety solutions to support your organizational needs in contractor compliance and management, employee and asset safety, reporting and analytics, and more. Speak to one of our safety experts today to find out how we can help you avoid OSHA violations and strengthen your safety program.

Learn How You Can Get EcoOnline North America

Complete this form and one of our safety experts will be in touch.