Share this Post

PUBLISHED

August 12, 2021

READ TIME

4 Minutes

WRITTEN BY

![]() Dina Adlouni

Dina Adlouni

Dina is the resident Content Writer at EcoOnline North America . When she’s not writing about health and safety, you’ll find her enjoying a cup of tea while watching her favorite sitcom.

Avoiding Ergonomic Hazards & Injuries in the Workplace

Ergonomic hazards and injuries can often be overlooked on the worksite, while safety professionals focus on larger risks which may be present. For this reason, ergonomic injuries are quite common and can be silently affecting your workforce.

Ergonomics can be described as the science behind ensuring a job or task is fit for a specific employee, to reduce any discomfort or injury. This may entail adjusting the equipment or tools used or modifying the task itself. Follow us as we describe the fundamentals of ergonomic hazards and highlight how to avoid such issues to keep your workforce safe.

Let’s dive in!

What is an Ergonomic Injury?

An ergonomic injury is one which results from prolonged strain, pressure, or incorrect posture due to a specific ergonomic hazard. Such injuries make up 33% of all worker injury and illnesses, according to the U.S. Bureau of Labor Statistics.

The most common type of ergonomic injury is a musculoskeletal disorder. Musculoskeletal disorders affect soft tissues such as muscles, ligaments, tendons and can even affect spinal discs which may injure the neck, shoulder, back, knee, foot and other areas. Other common ergonomic injuries include carpel tunnel syndrome, lower back injuries, and tendinitis.

What Could be a Cause of an Ergonomic Injury?

Ergonomic injuries are caused by repeated strain or pressure put on the body for a prolonged amount of time. These injuries do not appear immediately but take time to surface as the action is repeated over and over again.

Five Aspects of Ergonomics

When thinking about ergonomics in the workplace, there are five variables to consider:

1. Safety: Keep employees safe by designing the task or job to fit them, to avoid common ergonomic injuries mentioned earlier.

2. Comfort: Provide comfort with the tools used on the job and PPE worn by the workforce so as not to put a strain on the employee while working.

3. Ease of use: Ergonomics is meant to help workers simplify the tasks they are doing, avoiding any injury or stress on the body. By tailoring each task to the individual, jobs can be made a bit easier on the body.

4. Productivity: Productivity and performance can rise with jobs now putting less strain on the body and less injuries and time away from work.

5. Aesthetics: Aesthetics relates to how individuals respond to things. If something is pleasing and easy on the eyes, it can provide a certain aesthetic to the workplace and improve mood.

OSHA Ergonomics Standards

With musculoskeletal disorders being one of the most frequent reasons for lost or restricted worktime according to the Occupational Safety and Health Administration (OSHA), these ailments account for about 70 million visits to the doctor in the US every year, according to the Centers for Disease Control and Prevention (CDC). With this in mind, EHS professionals must take all measures to protect their employees and keep them safe.

OSHA has recommended compliance standards and a process to be put in place to help reduce ergonomic risks and hazards, with the following key factors:

- Support from senior management: Senior leaders must be heavily invested in this process and help to craft and communicate the goals for this initiative with the organization.

- Worker involvement: Ask employees for help identifying ergonomic hazards on-site and implementing corrective actions that can be put in place to mitigate risks. They can also assist in evaluating the efficacy of corrective actions made during the process.

- Training opportunities: The workforce must be given training concerning the importance of ergonomics in the workplace, how to identify such risks, and the need to report symptoms early.

- Early reporting of symptoms: Serious injuries and lost time can be avoided if workers report symptoms early so corrective actions can be taken to alleviate any stress or strain. This can also help when identifying risks to uncover hidden hazards.

- Solutions to control hazards: Once all hazards are identified, solutions must be put in place to help minimize risks.

- Periodic evaluation of progress: The ergonomics process must be assessed at regular intervals to uncover any gaps and find opportunities for improvement. This is a continuous process which will help the organization reduce ergonomic injuries year after year.

Avoiding Ergonomic Issues and Problems

Once your ergonomics process is put in place, begin by conducting an ergonomics hazard assessment on-site. This is one of the most effective ways to identify possible hazards.

According to OSHA, EHS professionals should consider certain factors such as whether workers have been diagnosed with common ergonomic injuries, if they perform repetitive tasks or ones which require awkward positions or postures, and whether high impact or vibration inducing tools are used regularly. It’s important to evaluate every job task for specific ergonomics risks and implement corrective actions to reduce them.

This is also a great opportunity to encourage worker involvement to provide any feedback. If feedback is received, assess it and consider conducting a job specific assessment to gauge the posture and movements carried out by the employee while completing the task.

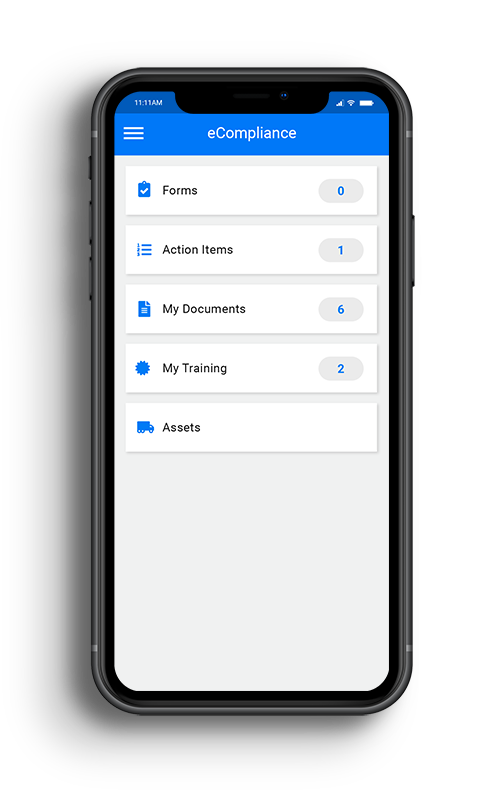

Consider using OSHA’s Ergonomic Assessment Checklist to help you conduct your hazard assessments on-site. Tracking this digitally can help streamline your processes and save time.

Stay ahead of workplace injuries by implementing a proactive safety approach, such as the Plan, Do, Check, Act cycle. Not sure what that entails? Download the free whitepaper, Introducing Continuous Improvement as a Competitive Advantage to learn more!

Learn How You Can Get EcoOnline North America

Complete this form and one of our safety experts will be in touch.