Share this Post

PUBLISHED

December 15, 2021

READ TIME

8 Minutes

WRITTEN BY

![]() Dina Adlouni

Dina Adlouni

Dina is the resident Content Writer at EcoOnline North America . When she’s not writing about health and safety, you’ll find her enjoying a cup of tea while watching her favorite sitcom.

Most Common OSHA Violations in 2021

The Occupational Safety and Health Organization has released its annual list of the top 10 OSHA violations in 2021. This list encompasses the most common OSHA violations which have been spotted in the workplace this year. It’s important all EHS professionals stay up to date with these OSHA violations to help ensure they are creating a safe work environment and avoiding hefty fines for a lack of compliance.

As we look back on the year, it’s important to reflect and learn from our mistakes, so more employees are protected in the future. Join us as we shed light on the top ten osha violations and what you can do maintain compliance, to have a healthier, safer, and stronger 2022.

1. Fall Protection – General Requirements (29 CFR 1926.501)

Fall protection is the number one OSHA violation for the 11th year in a row, with 5,271 violations seen this year1. This standard highlights fall protection guidelines to help keep workers safe who are working on walking/working surfaces without protected sides, above 6 feet. It mentions where safety systems are required, what systems to use, in addition to the implementation of these systems.

3,0761 of the violations mentioned above, were in relation to 1926.501(b)(13) which states: “Each employee engaged in residential construction activities 6 feet or more above lower levels shall be protected by guardrail systems, safety net systems, or personal fall arrest systems unless another provision in paragraph (b) of this section provides for the alternate fall protection measure”.2

You can avoid this violation by ensuring all walking/working surfaces are assessed and tested for stability before employees begin working on them, and by making sure proper safety systems such as guardrails, safety nets, or personal fall arrest systems are in place.

Read more on fall protection directly from OSHA.

2. Respiratory Protection – General Industry (29 CFR 1910.134)

Jumping up one spot from third place in 2020, respiratory protection is still a common OSHA violation, with 2,521 violations seen in 20211.COVID-19 and its variants continue to pose a threat to society, so it is essential for all EHS professionals to ensure workers are given the appropriate training and tools to maintain the health of their respiratory system in the workplace.

To remain compliant with this standard, organizations should have a respiratory protection program in place, with requirements regarding its administration, procedures, training, the use of respirators and more. The top two sections which were attributed to 618 and 519 of the violations above1, were in reference to providing a medical evaluation to employees to assess their ability to use a respirator before using it in the workplace as well as ensuring employees are fit tested before using a respirator for the first time, when it is changed, and on a yearly basis.

Take all the steps necessary to protect the respiratory health of your workforce by avoiding the above violations and ensuring a written respiratory protection program is implemented and communicated, as well as providing the necessary training with the appropriate PPE.

Read more on respiratory protection directly from OSHA.

3. Ladders – Construction (29 CFR 1926.1053)

Ranked 5th last year, ladder safety has climbed up to 3rd in 2021. 2,018 total violations were seen, with over 50% of violations1 coming from section 1926.1053(b)(1) which states: “When portable ladders are used for access to an upper landing surface, the ladder side rails shall extend at least 3 feet (.9 m) above the upper landing surface to which the ladder is used to gain access; or, when such an extension is not possible because of the ladder’s length, then the ladder shall be secured at its top to a rigid support that will not deflect, and a grasping device, such as a grabrail, shall be provided to assist employees in mounting and dismounting the ladder. In no case shall the extension be such that ladder deflection under a load would, by itself, cause the ladder to slip off its support”3.

Shockingly, 244 violations1 were attributed to ladders not being used for their designed purpose. EHS professionals must make sure all workers receive the proper training when it comes to properly choosing and using ladders, in addition to inspecting them for damage.

Read more on ladder protection directly from OSHA.

4. Scaffolding, General Requirements – Construction (29 CFR 1926.451)

In the same spot as 2020, scaffolding remains 4th on the list of OSHA violations, with 1,943 total violations1. EHS professionals must ensure measures are taken to protect all workers working on scaffolding 10 feet or higher from falling or falling objects.

This can be done by having all scaffolding designed by someone who is qualified and placing guardrails to protect employees working on these structures. Scaffolding must also be regularly inspected, and workers should receive proper training concerning working on such structures.

Read more on scaffolding directly from OSHA.

5. Hazard Communication – General Industry (29 CFR 1910.1200)

Dropping three spots from 2020, Hazard Communication is number 5 on the list with 1,939 violations seen in 20211. This hazard communication standard is in reference to chemical hazards and how they are communicated across the organization.

Organizations must have a written hazard communication program which discusses worker training, warning labels, safety data sheets and more. This must also be implemented with employers providing training on hazardous chemicals and access to safety data sheets to employees.

Read more on hazard communication directly from OSHA.

6. Control of Hazardous Energy (Lockout/Tagout) – General Industry (29 CFR 1910.147)

Number 6 on the list is control of hazardous energy in relation to lockout/tagout. A total of 1,670 OSHA violations were seen this year with the most cited violations relating to energy control procedures as well as training and communication1.

It is vital that safety professionals have clear, written procedures and processes in place, when dealing with machinery. Inefficient lockout/tagout methods could lead to injuries like shocks or burns, so it is imperative proper procedures are drafted and communicated to the workforce. Training must also be provided so all employees understand these lockout/tagout methods to protect them against any risks or hazards.

Read more on lockout/tagout directly from OSHA.

7. Fall Protection – Training Requirements (29 CFR 1926.503)

Training requirements in relation to fall protection is another common OSHA violation. Fall protection has been the number one OSHA violation for 11 years in a row, so it’s no surprise that training requirements would be a primary area of concern.

Of the 1,6660 total violations, 1,134 were in relation to employers providing a training program to employees who may be subject to falls1. EHS professionals must ensure that employees know how to identify risks and hazards related to falls and understand what steps to take to mitigate them. It’s important to also have a written record of this training and certification.

Read more on fall protection training requirements directly from OSHA.

8. Eye and Face Protection (29 CFR 1926.102)

With violations rising from 1,369 in 2020 to 1,451 this year1, proper personal protective equipment in relation to eye and face protection is another OSHA violation. Workers can be exposed to hazards such as flying particles or harmful chemicals in the workplace, so having the right PPE is vital. Workers must be trained in how to properly use this PPE and be encouraged to wear it whenever necessary to avoid any injury or illness.

Of the 1,451 seen this year, 1,410 were in relation to standard 1926.102(a)(1) which states: “The employer shall ensure that each affected employee uses appropriate eye or face protection when exposed to eye or face hazards from flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors, or potentially injurious light radiation”4.

Read more on eye and face protection directly from OSHA.

9. Powered Industrial Trucks – General Industry (29 CFR 1910.178)

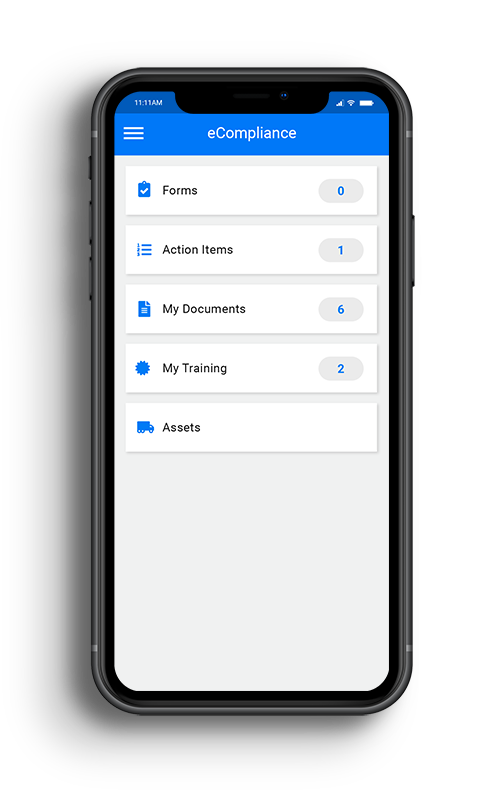

Employees who use powered industrial trucks such as tractors or forklifts must be properly trained beforehand and at regular intervals to help avoid risks and hazards. This OSHA violation discusses violations which are in reference to equipment maintenance and operation, in addition to employee training.

Properly maintaining assets to protect against equipment failure or malfunction is an important element to creating a safe working environment. The EcoOnline asset inspection solution helps EHS professionals stay proactive when it comes to minimizing risks related to equipment or machinery on-site. Learn more by speaking to one of our safety experts.

Read more on powered industrial trucks directly from OSHA.

10. Machinery and Machine Guarding – General Requirements (29 CFR 1910.212)

Last on the list is machinery and machine guarding. Having the right machine guards in place is important to protect workers from hazards such as sparks, flying objects, and more. The organization must ensure the right types of guards are in place and workers are trained properly when using these types of machinery to minimize risks.

Read more on machinery and guarding directly from OSHA.

Our team wants to help you prepare for a strong year ahead by helping you avoid OSHA violations and stay compliant with OSHA standards. The EcoOnline suite of solutions provides support for employee and asset safety, contractor management, reporting and analytics, and more.

Speak to one of our safety experts or fill out the form below to find out how we can help your organization be prepared for your next OSHA inspection.

References:

1 Kevin Druley, OSHA’s Top 10 Most Citation Violations for FY 2021, Safety and Health Magazine, Nov. 2021

2 Occupational Safety and Health Administration, 1926.501 – Duty to have fall protection

3Occupational Safety and Health Administration, 1926.1053 – Ladders

4 Occupational Safety and Health Administration, 1926.102 – Eye and face protection

Learn How You Can Get EcoOnline North America

Complete this form and one of our safety experts will be in touch.