Share this Post

PUBLISHED

November 7, 2022

READ TIME

6 Minutes

WRITTEN BY

![]() Dina Adlouni

Dina Adlouni

Dina is the resident Content Writer at EcoOnline North America . When she’s not writing about health and safety, you’ll find her enjoying a cup of tea while watching her favorite sitcom.

What are the IOGP Life Saving Rules for Safety in the Oil and Gas Industry?

The oil and gas industry is one which is filled with dangers, as the fatality rate for workers in this industry is seven times higher than others. It is for this reason that the International Association of Oil and Gas Producers (IOGP) wrote life saving rules to help make sure workers go home safely at the end of the day.

These rules are standardized across the oil and gas industry to establish a strong foundation for all organizations to follow to keep their workforce and third-party contractors safe. Each of the rules can be used as a focal point for team training and communication.

9 Life Saving Rules to share with your oil and gas team

The following nine rules are based on data of activities which have been the cause of most fatalities in this industry. It is vital that you share these with your team and third-party contractors, as well as the recommended actions to help prevent fatalities. Workers should not be permitted to start work on-site until these rules are discussed.

1. Bypassing safety controls

This rule focuses on ensuring all safety controls are in place and specific procedures are always followed by your teams. Workers and third-party contractors must have a full understanding of the equipment they use and the required procedures. They must also get permission before disabling safety equipment, not following procedures, or crossing a barrier.

Human error is only natural. By ensuring this rule is followed, you can help to strengthen your organization’s safety culture and sense of accountability for each other’s safety. Learn more on this in our guide on Human and Organizational Performance: How to Strengthen Your Safety Management System with Human and Organizational Performance.

2. Confined space

Confined spaces are a major risk as they could contain noxious gases, harmful chemicals or could even cave in. Workers and third-party contractors must ask permission before entering a confined space and be extremely careful when inside such areas. A rescue plan must be in place and someone must be close by, in case something happens. The space must be tested and assessed for hazards and energy sources must be isolated. Workers must also use their breathing masks if needed.

3. Driving

Transportation incidents result in two thirds of fatalities in the oil and gas industry. This includes vehicle crashes due to unsafe driving. This rule highlights the fact that all workers must wear a seatbelt and adhere to speed limits. Workers must also avoid driving when tired or unfit to do so and avoid using phones while on the road at all times.

Practicing safe driving and adhering to these rules can not only help to save your life but also those who may be in the vehicle with you.

4. Energy isolation

It is vital to ensure energy is isolated and all lockout/tagout procedures are completed before dealing with specific equipment. If this is not done, workers could be subject to electrocution, shocks, burns, and more. For this reason, all energy sources must be identified, isolated, and/or locked and tagged out, according to the IOGP.

5. Hot work

Fire hazards and ignition sources resulting from hot work, could create a major risk to your employees. Hot work includes any duties or tasks which could result in a fire hazard through various ignition sources, like sparks or flames. To avoid fires, workers should remove any flammable material which may be present and get permission to begin their hot work. They must also control any ignition sources which may be created.

When working in hazardous areas where gases may be present, gas tests must be completed and all gases should be regularly monitored. It is essential that workers conduct these tests to avoid explosions.

6. Line of fire

This rule highlights the idea that workers should stay out of harm’s way and help others to do the same. According to the IOGP, this includes avoiding “moving objects, vehicles, pressure release, and dropped objects.” According to OSHA, three out of every five fatalities in this industry are caused by struck by’s or caught in between incidents. They must also not venture into restricted areas and report any dropped objects which may be found in the area.

This rule will also strengthen the safety culture at your organization and create a greater sense of accountability among the workforce for each other’s safety.

7. Safe mechanical lifting

The workforce is always subject to danger when heavy loads are being lifted. For this reason, safety procedures must be taken during this process. This includes making sure that the equipment being used and the load being lifted have been inspected. The worker must also only use equipment they are trained to use and should never walk under an area where a load is being lifted, respecting all barriers which may be present.

8. Work authorization

Your teams and third-party contractors should always have the proper permit to work. They must also be given authorization to work on site and assess the area and equipment before starting work. All hazards must be controlled before starting work and should begin when it is safe to do so. It is also vital that when handing work over to other team members, they ensure that all hazards are controlled, and it is safe to begin work.

9. Working at heights

Falls are a true threat to workers on site when working at heights, with 86% of fatalities due to inadequate fall protection. Your entire workforce as well as third-party contractors should know how to properly inspect fall protection equipment and use it when necessary. They must also only use approved anchor points and prevent objects from failing while working at heights.

How Can EcoOnline Help?

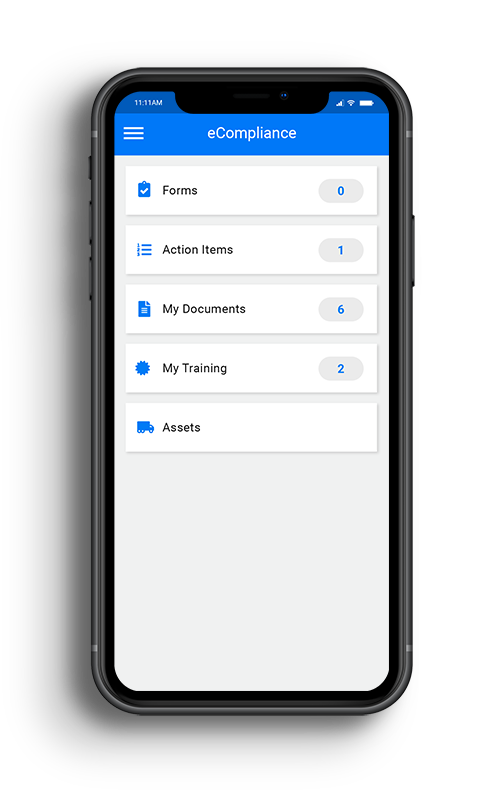

The EcoOnline solution can help keep your workforce safe with its dynamic capabilities relating to the 9 life saving rules:

- Bypassing Safety Controls: Explore 100+ hazard categories and descriptions, 40+ controls, and customizable risk ratings with the EcoOnline EHS management solution’s hazard assessment module. Keep your workforce safe by providing detailed hazard descriptions, controls, risk ratings, and steps to complete tasks safely with the ability to make sure that all workers have read the aforementioned elements to avoid bypassing safety controls. Moreover, discover the ability to conduct safety meetings and toolbox talks on the above nine life saving rules with your team within our solution, while being able to record who attended the meeting and what was discussed.

- Energy Isolation: The ability to perform lockout/tagout procedures digitally using automation, can help mitigate risks related to energy isolation. Gain 360-degree visibility into all LOTO procedures and KPIs, with key stakeholders notified of any activity in real time.

- Confined Spaces: Ensure all relevant front-line staff are trained in identifying fire and explosion hazards associated with site activities, through our training management capabilities. Assign Confined Spaces eLearning courses to any/all employees that need to be trained on this job activity, issue eLearning course certificates for workers to have in their digital wallet to always have their certificates on hand.

- Line of Fire: With the EcoOnline EHS management solution, employees can stay out of the line of fire and help others to do so as well by reporting near misses, equipment damage, incidents, and more right from their phones.

- Safe Mechanical Lifting: The EcoOnline asset inspection solution helps to proactively protect against equipment failure or malfunction. You can even choose from a variety of existing inspection templates for cranes, forklifts, rigging, and more.

- Working at Heights: Conduct fall protection equipment inspections with our asset inspection solution to help your team check that assets are working properly. Identify unsafe behavior that may be associated with working at heights through digital behavior-based safety observations as well, right from a mobile phone. Explore the aforementioned hazard assessment capabilities to assess the area for any potential hazards to mitigate possible risks that may arise when working at heights.

- And much more!

To learn more about how the EcoOnline suite of solutions can help you protect your people in the oil and gas industry, speak to and EcoOnline representative today.

Learn How You Can Get EcoOnline

Complete this form and one of our safety experts will be in touch.