Share this Post

PUBLISHED

March 6, 2023

READ TIME

6 Minutes

WRITTEN BY

![]() Dina Adlouni

Dina Adlouni

Dina is the resident Content Writer at EcoOnline North America . When she’s not writing about health and safety, you’ll find her enjoying a cup of tea while watching her favorite sitcom.

Process safety management is critical when you are working with hazardous substances. According to standard 29 CFR 1910.119 otherwise known as the Process Safety Management of Highly Hazardous Chemicals set by the Occupational Safety and Health Administration (OSHA), organizations who work with harmful chemicals are required to comply with several elements. This will help mitigate hazards and risks related to potential toxic substances.

Learn more about process safety management to keep your workforce safe, as we dive into:

- What is process safety management?

- What are the 14 elements of process safety management?

- What is a process safety management program?

- How EcoOnline can help

What is Process Safety Management

Exposure to harmful substances can be a prime risk when working in certain industries, such as oil and gas and construction. This is why process safety management is key to helping create a safer work environment. Process safety management can be defined as the systems in place to help mitigate hazards related to dangerous chemicals.

What is a Process Safety Management Program

A process safety management program is a written program which follows the Process Safety Management of Highly Hazardous Chemicals standard outlined by OSHA. This includes 14 elements ranging from recording all process safety information and hazard analysis, to training and mechanical integrity. Your program must be communicated to all employees and easily accessible by key stakeholders.

What are the 14 elements of process safety management?

Let’s get more granular when it comes to the 14 elements of process safety management. Each of these elements have been mandated by OSHA to help employers protect their workforce from hazardous chemicals:

1. Process Safety Information

Document and communicate all information related to process safety, including hazardous chemicals which may be present during certain procedures or while using certain equipment, to your employees. This will provide guidance to your people on what hazards they should be aware of.

2. Process Hazard Analysis

Identify and analyze any hazards related to dangerous chemicals. If any nonconformances are found, work to mitigate them with the proper corrective actions conducted by the right stakeholders. Remember to record this entire process and repeat it at a regular cadence to strengthen your process safety program.

3. Operating Procedures

Record all operating procedures and include any information about how to safely complete job tasks which may involve hazardous chemicals. Don’t forget to include guidance on what to do when a hazard arises, what to do in an emergency state, what to do during normal operations, and more within your operating procedures.

4. Employee Participation

Protecting employees should never be one person’s responsibility. That’s why employers should empower all team members by reinforcing the idea that safety is a team effort. According to this element, employees must participate and collaborate with senior leadership in certain process safety management areas.

5. Training

Train all employees and third-party contractors to do their jobs safely. This includes knowing what to do if dangerous chemicals arise, receiving safety data sheets with information on harmful chemicals, and more. Keep a record of all courses and certifications that your employees have taken to present during an inspection, if needed.

6. Contractor Safety

Make sure all third-party contractors have the right qualifications needed before working on your site. Provide any training that may be needed before coming on site and remember to document this to prove that all employees are properly certified. It’s also important that you share any information that may be needed to contractors to conduct their job tasks safely.

7. Pre-Startup Safety Reviews

Conduct safety reviews before any new procedures or hazardous substances may potentially be involved in a process. This will help gauge if all the right pieces are in place before implementation. Pre-start up safety reviews include providing the right training to employees, communicating the new process to key stakeholders, and making sure all equipment is properly functioning and maintained.

8. Mechanical Integrity

Properly inspect and maintain all equipment and machinery used on site to protect against possible malfunction or failure. Keep a record of all inspections including information such as the date of the inspection, who performed it, what was being inspected, findings, and corrective actions.

9. Hot Work Permit

Hot work permits are a requirement before any hot work is conducted by an employee on site. Employers must implement specific fire prevention and protection requirements mandated by OSHA, to keep their workforce safe from possible sparks or a fire before any hot work takes place.

10. Management of Change

Follow procedures outlined by OSHA when it comes to management of change. This is when a change in process occurs at the organization. Document information on why the change is necessary, a timeline showing when it will be completed, how it will be implemented, how it will affect the organization and employees, and much more.

11. Incident Investigation

Investigate all incidents which have occurred at your organization within 48 hours of the incident. A team which includes an expert in that area, must conduct the investigation and record the date and time of the incident, who was involved, what happened, any corrective actions which were implement, and more.

12. Emergency Planning

You must have an emergency response plan in place, so all employees know what procedures to follow to protect each other during an emergency. When documenting your plan, make sure you have access to all the right resources like fire extinguishers, and that they are working properly. Make sure all employees have access to your plan and understand it, and conduct the necessary training at a regular cadence.

13. Compliance Audits

It’s always important to maintain compliance within your industry. Take the time to audit your process safety management program to identify any potential weaknesses or deficiencies, prioritize them, and implement the right corrective actions to strengthen your processes. OSHA recommends employers do this at a 3-year cadence.

14. Trade Secrets

Lastly, no information should be kept from third-party contractors or employees who may affected by any of the above. This is vital when it comes to creating a safer work environment and protecting your employees. This will help make sure that all company and industry guidelines are followed by everyone at the work site.

How EcoOnline Can Help

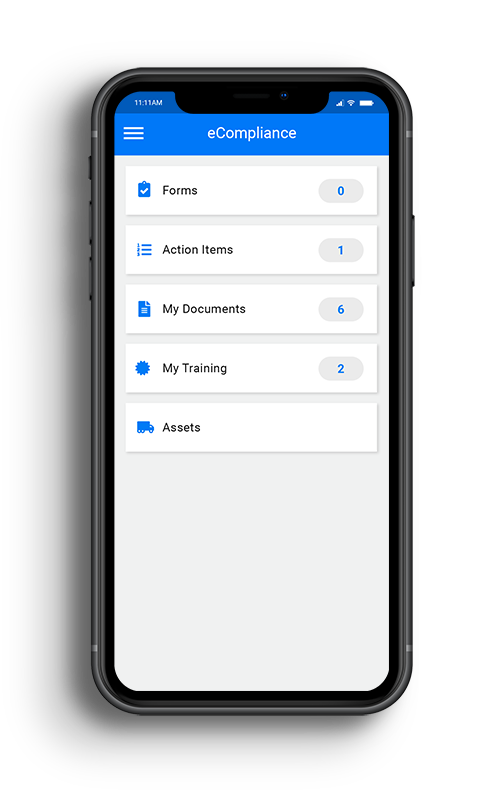

We want to help you create a safer workplace for your people. Our health and safety solutions can help you comply with many of the above elements, including:

- Employee participation: Empower employees with a mobile EHS solution to work uninterrupted no matter where they may be located and gain insight into participation and engagement rates.

- Training: Gain access to 300+ courses through our extensive eLearning library and track employee training.

- Process hazard analysis: Streamline process hazard analysis with 100+ hazard categories and descriptions, customizable risk ratings, and 40+ controls.

- Incident investigations: Conduct investigations on incidents as well as root cause analysis, and mitigate hazards quickly through our corrective action notification set-up.

- Mechanical integrity: Properly maintain equipment and machinery, protecting against malfunction or failure with the help of our asset inspection solution.

- Management of change: Record all procedures and processes involved in your organization’s management of chance through custom forms, and capture digital signatures easily within our platform.

- Compliance audits: Assess your process safety management program through custom audits and assign corrective actions if nonconformances are identified.

- And much more!

To learn more about how we can help you, fill out the form below or speak to one of our EcoOnline representatives.

Learn How You Can Get EcoOnline

Complete this form and one of our safety experts will be in touch.